Embark on an extraordinary journey with Six Sigma Yellow Belt Answers, where we unravel the secrets to process improvement and organizational excellence. From understanding the fundamentals to mastering practical applications, this comprehensive guide will empower you to elevate your career and drive tangible results.

Delve into the world of Six Sigma, where data-driven decision-making and continuous improvement reign supreme. Discover the tools, techniques, and methodologies that empower Yellow Belts to identify and eliminate inefficiencies, enhance quality, and maximize customer satisfaction.

Six Sigma Yellow Belt Overview: Six Sigma Yellow Belt Answers

Six Sigma Yellow Belt certification is an introductory-level training program designed to provide individuals with a foundational understanding of Six Sigma methodologies and tools. It equips them with the knowledge and skills to contribute to process improvement projects within their organizations.

Purpose and Objectives

- Develop a basic understanding of Six Sigma principles and methodologies.

- Gain practical knowledge of data analysis, problem-solving, and process improvement tools.

- Enhance problem-solving and decision-making abilities.

- Contribute effectively to Six Sigma projects and initiatives.

Role and Responsibilities

Six Sigma Yellow Belts typically serve as team members in larger Six Sigma projects or lead smaller-scale improvement initiatives within their own work areas. Their responsibilities may include:

- Collecting and analyzing data

- Identifying and solving process problems

- Developing and implementing improvement solutions

- Monitoring and evaluating project results

Six Sigma Yellow Belt Training

Six Sigma Yellow Belt training is designed to provide individuals with the foundational knowledge and skills required to participate effectively in Six Sigma projects. This training typically covers a range of key modules, including:

Key Modules in Six Sigma Yellow Belt Training

- Introduction to Six Sigma and its principles

- Understanding process variation and measurement

- Data collection and analysis techniques

- Root cause analysis and problem-solving methodologies

- Process improvement tools and techniques

- Project management and stakeholder engagement

Practical application and project work are crucial components of Six Sigma Yellow Belt training. These elements allow participants to apply their newly acquired knowledge and skills to real-world scenarios. By working on actual projects, individuals gain hands-on experience in identifying and addressing process inefficiencies, leading to tangible improvements in their organizations.

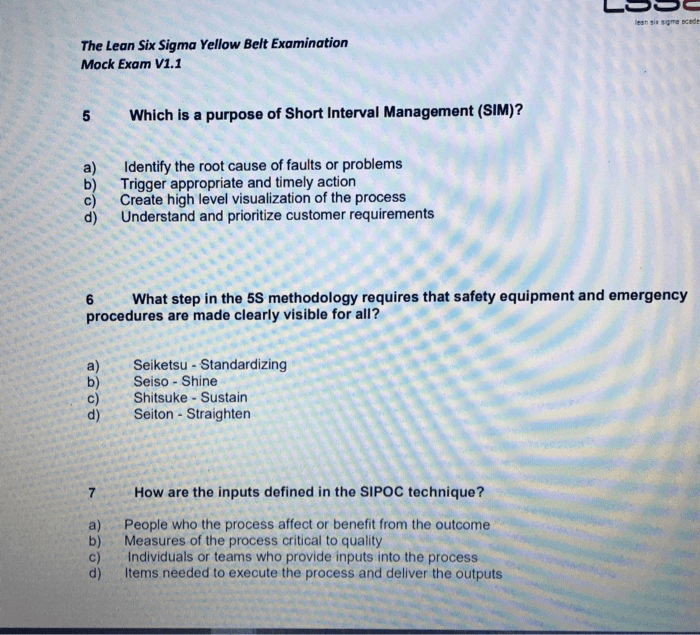

Six Sigma Yellow Belt Tools and Techniques

Six Sigma Yellow Belts are equipped with a comprehensive toolkit to analyze, solve problems, and improve processes. These tools and techniques are essential for driving continuous improvement and enhancing organizational performance.

Data Collection and Analysis Tools

- Pareto Charts:Visualize data to identify the most frequent problems or causes.

- Histograms:Display the distribution of data to identify patterns and variations.

- Control Charts:Monitor process stability and identify special causes of variation.

Process Improvement Tools

- Cause-and-Effect Diagrams (Fishbone Diagrams):Identify and categorize potential causes of problems.

- 5 Whys:Iteratively ask “why” to uncover the root cause of a problem.

- Value Stream Mapping:Visualize the flow of materials and information through a process to identify waste and inefficiencies.

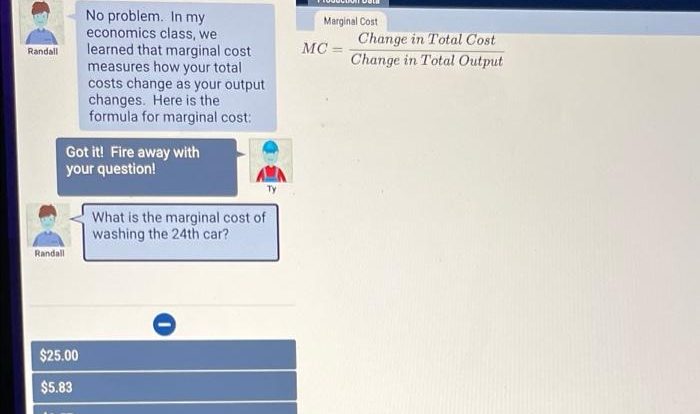

Statistical Tools, Six sigma yellow belt answers

- Hypothesis Testing:Determine if there is a statistically significant difference between two or more groups.

- Regression Analysis:Model the relationship between variables to predict outcomes and identify key drivers.

- Analysis of Variance (ANOVA):Compare the means of multiple groups to determine if there are significant differences.

Six Sigma Yellow Belt Project Management

Effective project management is crucial for the success of Six Sigma Yellow Belt initiatives. The process involves defining the project scope, gathering and analyzing data, and implementing solutions to improve processes.

Data plays a vital role in Six Sigma projects. It provides insights into process performance, helps identify root causes of problems, and supports decision-making. Yellow Belt projects typically focus on smaller-scale improvements, but the principles of data collection, analysis, and interpretation remain the same.

Project Definition

The first step in project management is to define the project scope, objectives, and deliverables. This includes identifying the problem or opportunity that the project will address, as well as the desired outcomes.

Data Collection

Once the project scope is defined, data collection begins. Data can be collected from various sources, such as process observations, interviews, and historical records. The type of data collected depends on the project objectives and the specific process being analyzed.

Data Analysis

Once data is collected, it is analyzed to identify trends, patterns, and root causes of problems. Statistical tools, such as control charts and histograms, are often used to analyze data and identify areas for improvement.

Solution Implementation

Based on the data analysis, solutions are developed and implemented to address the identified problems. These solutions may involve process changes, new procedures, or training for employees.

Monitoring and Evaluation

After solutions are implemented, it is important to monitor their effectiveness and make adjustments as needed. This involves tracking key performance indicators and collecting feedback from stakeholders to ensure that the project is meeting its objectives.

Six Sigma Yellow Belt Certification

The Six Sigma Yellow Belt certification process involves attending a comprehensive training program and passing an exam. The training typically covers the fundamental concepts of Six Sigma, including process improvement methodologies, data analysis techniques, and project management principles.

Benefits of Certification

Obtaining Six Sigma Yellow Belt certification offers several benefits:

- Demonstrated proficiency in Six Sigma methodologies

- Enhanced problem-solving and analytical skills

- Improved process efficiency and quality

- Increased career opportunities in quality management and process improvement

Career Opportunities

Certified Six Sigma Yellow Belts are in high demand in various industries, including manufacturing, healthcare, finance, and technology. They can pursue roles such as:

- Process Improvement Specialist

- Quality Control Engineer

- Business Analyst

- Project Manager

Six Sigma Yellow Belt Applications

Six Sigma Yellow Belt principles find widespread applications across diverse industries, from manufacturing to healthcare and finance. By employing data-driven approaches, organizations can enhance efficiency, reduce defects, and improve customer satisfaction.

Manufacturing

In manufacturing, Six Sigma Yellow Belts play a crucial role in optimizing production processes. They analyze data to identify and eliminate waste, streamline operations, and reduce cycle times. By implementing Six Sigma tools such as DMAIC (Define, Measure, Analyze, Improve, Control), they can improve product quality, reduce defects, and increase productivity.

Healthcare

In healthcare, Six Sigma Yellow Belts contribute to improving patient care and reducing costs. They apply Six Sigma principles to enhance patient safety, streamline administrative processes, and reduce medical errors. By analyzing data on patient outcomes, they can identify areas for improvement and develop evidence-based interventions to enhance the quality of care.

Finance

In the finance industry, Six Sigma Yellow Belts help optimize financial processes, reduce risks, and improve compliance. They analyze financial data to identify and mitigate risks, streamline accounting procedures, and enhance operational efficiency. By implementing Six Sigma tools, they can improve financial performance, reduce costs, and enhance stakeholder confidence.

Questions and Answers

What is the primary objective of Six Sigma Yellow Belt certification?

To provide individuals with the knowledge and skills to identify and solve problems, improve processes, and enhance quality within an organization.

What are the key responsibilities of a Six Sigma Yellow Belt?

To support Six Sigma projects, collect and analyze data, identify and implement process improvements, and contribute to continuous improvement initiatives.

What is the significance of practical application and project work in Six Sigma Yellow Belt training?

Practical application and project work allow individuals to apply their knowledge and skills in real-world scenarios, reinforcing their understanding and enhancing their problem-solving abilities.

How does Six Sigma Yellow Belt contribute to business outcomes and customer satisfaction?

By identifying and eliminating inefficiencies, enhancing quality, and reducing waste, Six Sigma Yellow Belt principles lead to improved operational performance, increased customer satisfaction, and overall business success.